Spa Design At Its Finest

At Strong Spas, we combine innovation with meticulous craftsmanship at our state-of-the-art facility in Northumberland, Pennsylvania. Our spas undergo a stringent nine-phase quality control process, ensuring durability and exceptional performance. With industry-leading technologies like our Triple-Bond Acrylic Shell for unmatched strength, and advanced rotational molding techniques, we create spas built to last. Every spa is custom-made, adhering to the highest standards and backed by a Lifetime Warranty. Discover premium quality and lifetime memories with Strong Spas.

A Legacy of Premium Craftsmanship

At Strong Spas, each hot tub is meticulously custom-built, never mass-produced, ensuring the highest level of quality. Every spa undergoes rigorous quality control before being shipped to over 40 countries worldwide. Our commitment to excellence means that no detail is overlooked, and we promise our customers nothing short of the best in luxury and durability.

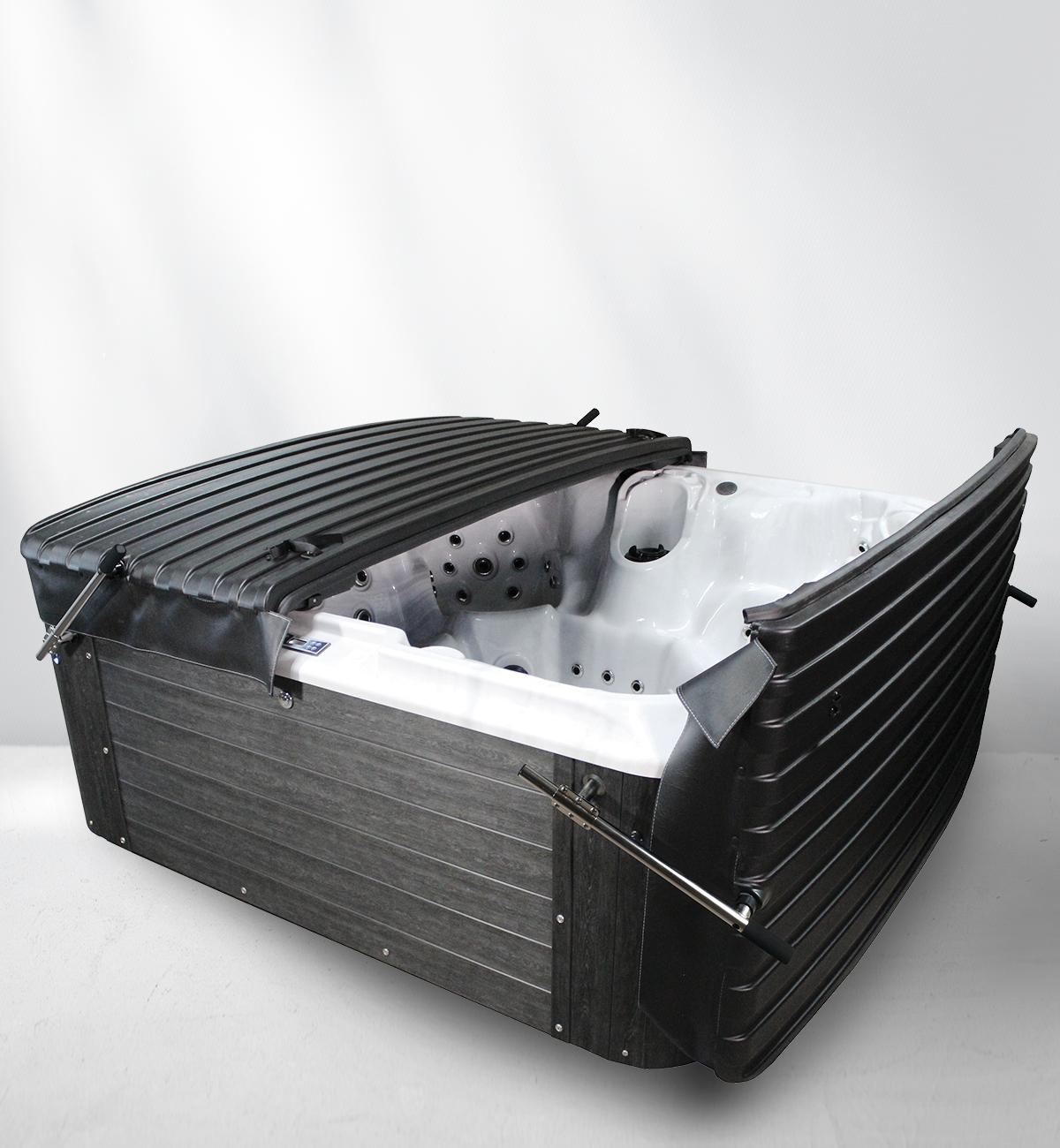

Built to Endure

The longevity of your hot tub begins with the strength of its shell. Strong Spas use a triple-bond acrylic shell, engineered for the highest durability and the lowest maintenance. This unique three-layer process creates one of the toughest shells in the industry, ensuring every soak is a luxurious and lasting experience. With its unmatched strength and reliability, your Strong Spas hot tub is built to provide you and your family comfort and enjoyment for years to come.

Premium Shells

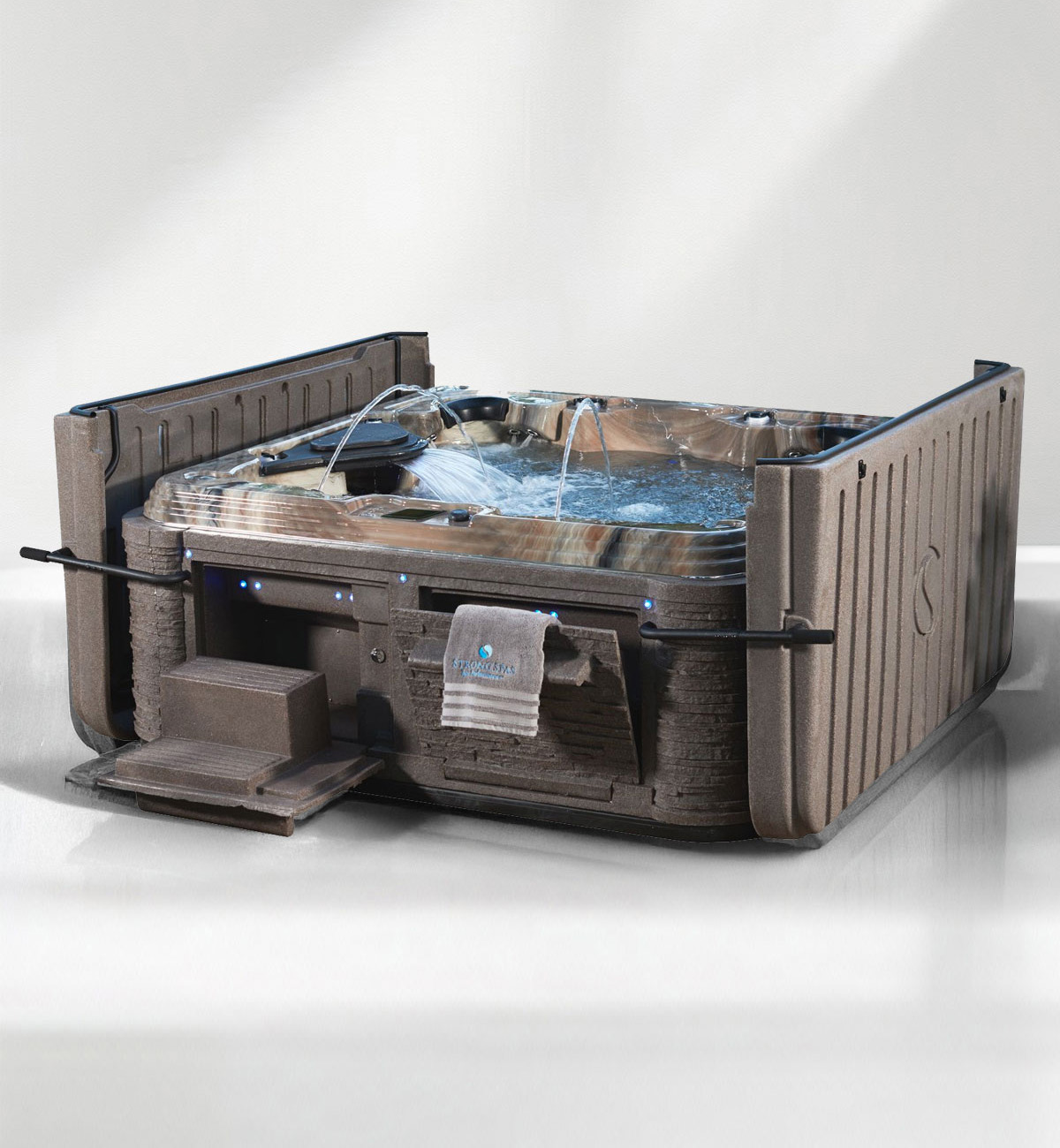

Rotational Molding

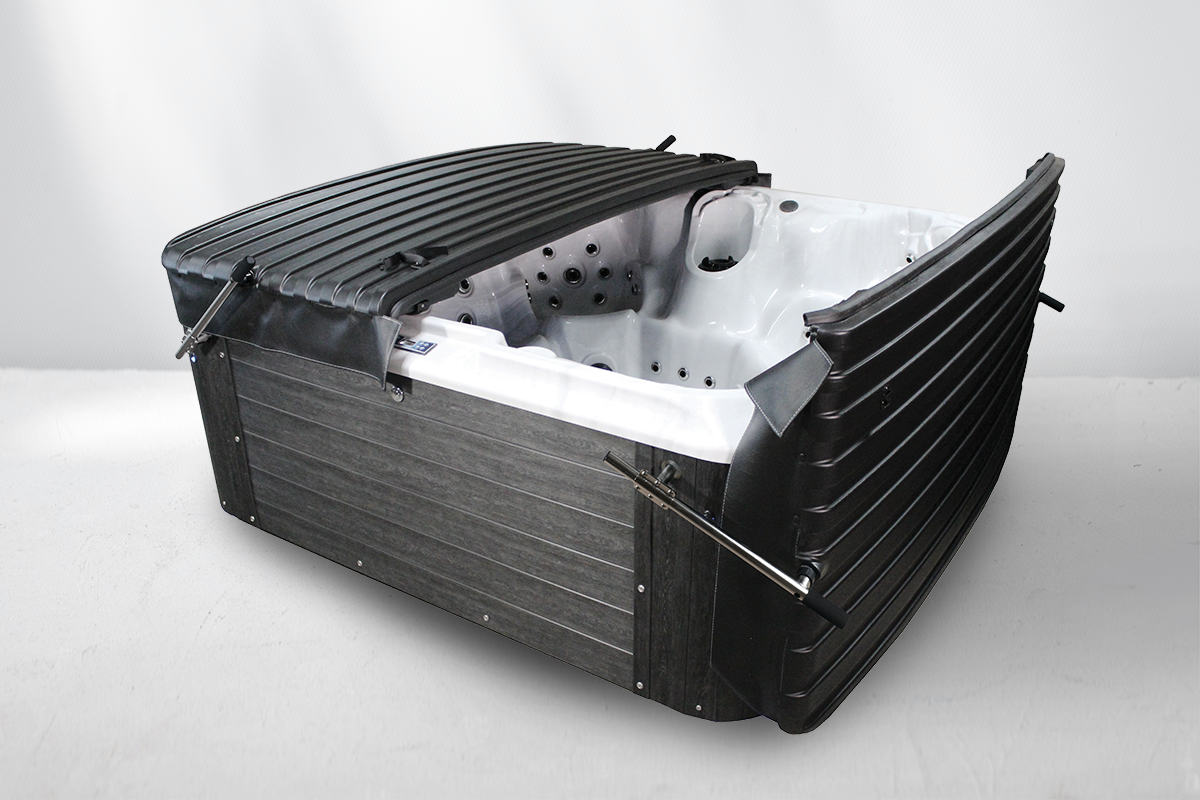

Our G-2 Series & Durasport Spas are built using an advanced rotomolding process. This method heats a hollow mold filled with high-impact polyethylene polymer, rotating it biaxially to create an even, durable coating. Strong Spas employs some of the largest and most advanced rotomolding machines to produce seamless, one-piece spas designed to last. The result is a hot tub with unparalleled strength and longevity, offering relaxation you can count on for years.

Backed By a Lifetime Warranty

At Strong Spas, our rotationally molded cabinets are engineered with consistent wall thickness and density, creating a structure so durable that we back it with a Lifetime Warranty. Built to last, your spa cabinet will maintain its beauty and strength for years, ensuring a reliable and luxurious experience from day one and beyond.

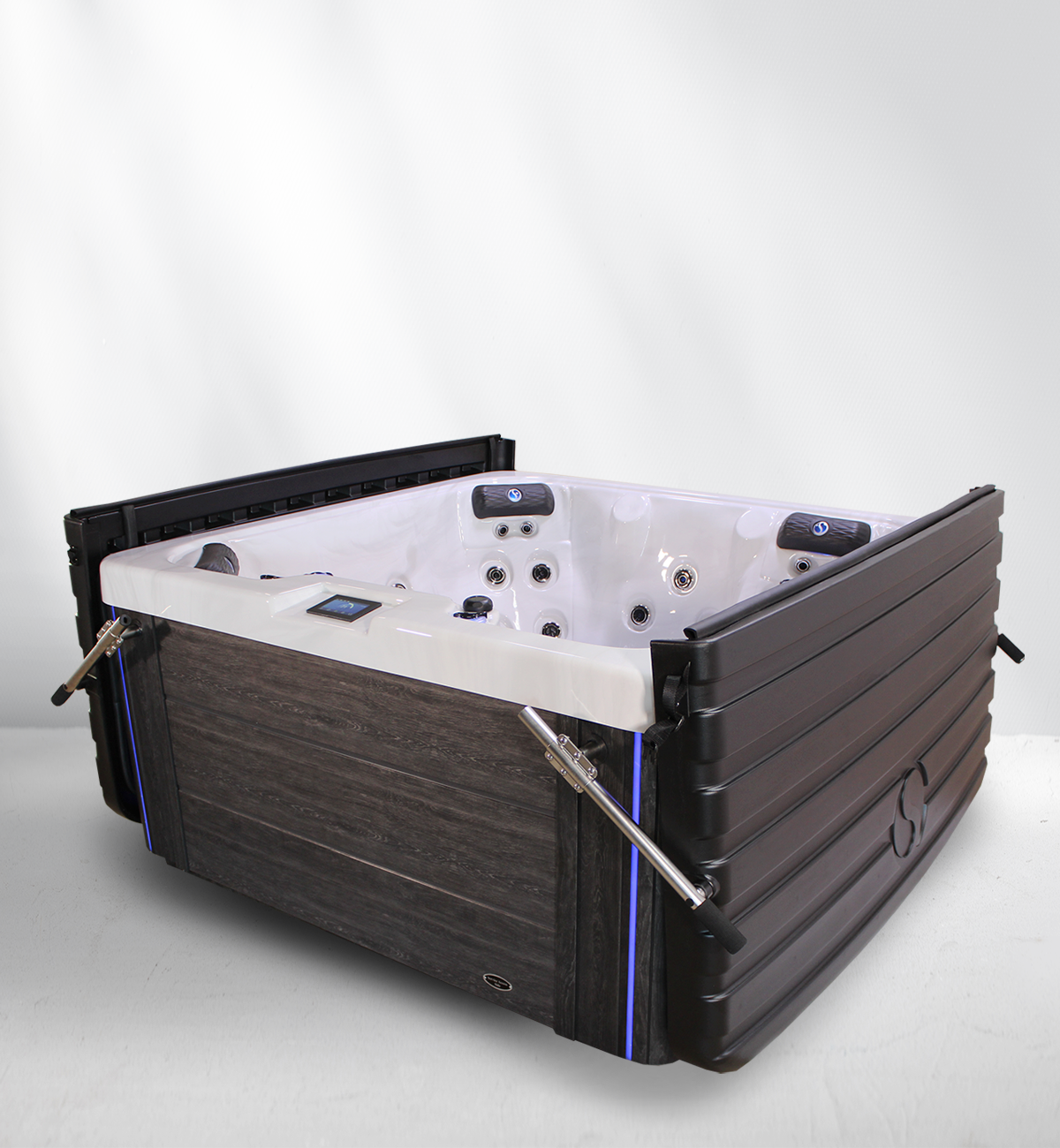

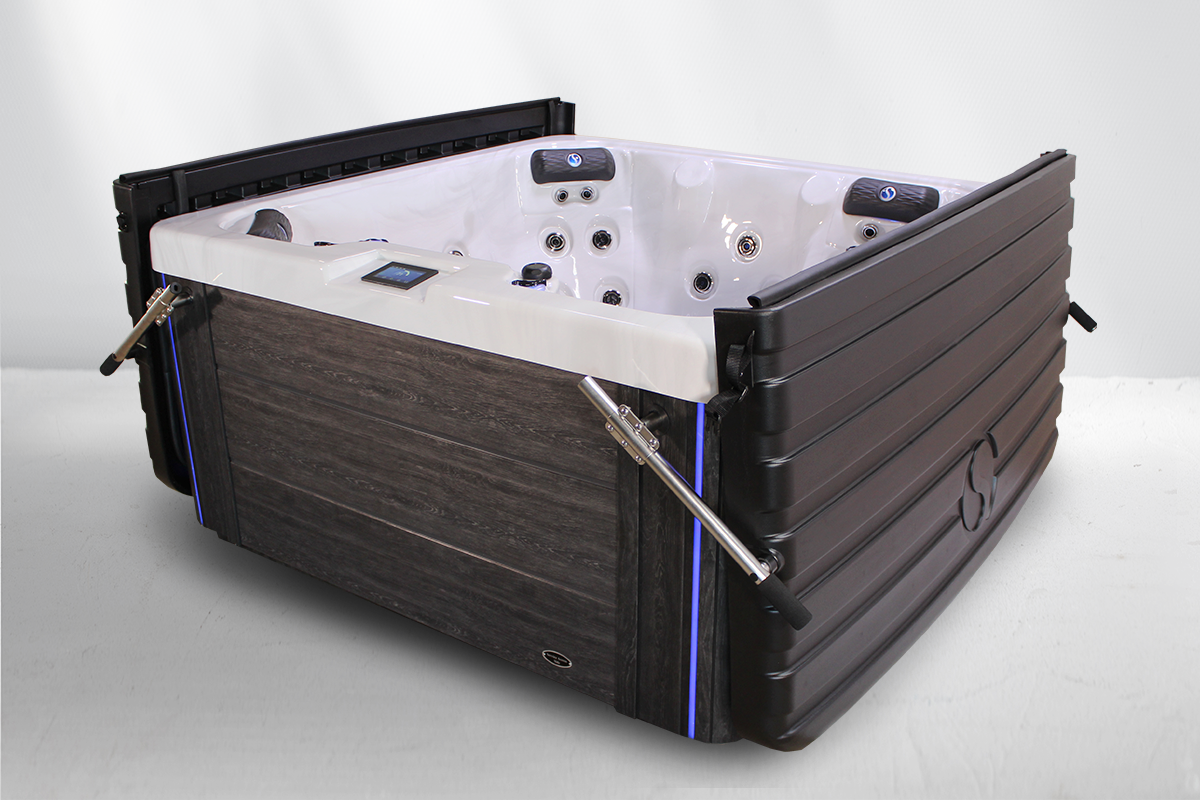

Strong Comfort. Luxury Features.

Our sleek, stylish Summit Series offers sophisticated opulence for the ultimate hydrotherapy experience. Our Strong Spas Summit Series seating is ergonomically designed for your maximum relaxation and rejuvenation. Combining eye-catching curb appeal with power and efficiency, the Summit Series is designed to bring you peace of mind and restoration for your body. We provide the spa. You make the memories.